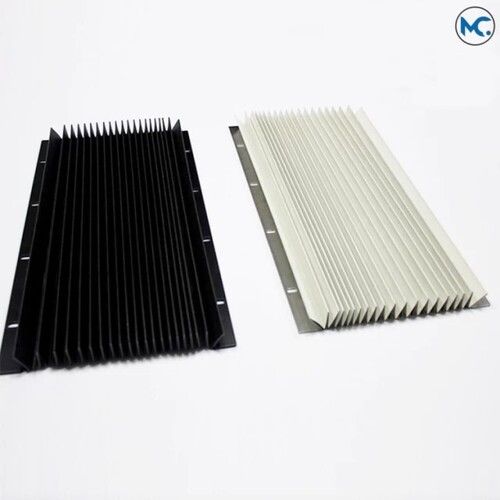

Rubber Coated bellows

Product Details:

- Color Black

- Usage Industrial

- Product Type Bellows

- Max. Temperature 60 Celsius (oC)

- Size Custom

- Head Code Round

- Surface Treatment Other

- Click to view more

Rubber Coated bellows Price And Quantity

- 500 INR/Unit

- 1 Unit

Rubber Coated bellows Product Specifications

- 60 Celsius (oC)

- Bellows

- Industrial

- Other

- Black

- Round

- Other

- Custom

- Others

- Others

- Others

Rubber Coated bellows Trade Information

- Cash on Delivery (COD) Cash in Advance (CID)

- 50 Unit Per Day

- 1 Week

- Yes

- Free samples are available

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

The rubber coating on these bellows serves multiple purposes. Firstly, it provides a durable and resilient outer layer that can withstand exposure to various substances and harsh conditions. The rubber coating also enhances flexibility, allowing the bellows to expand and contract smoothly without compromising their protective capabilities.

The primary function of rubber-coated bellows is to prevent the entry of dust, dirt, liquids, and other potentially damaging elements into the moving parts of machinery. This protection is crucial for maintaining the performance and longevity of equipment, reducing the risk of wear and tear.

These bellows find applications in diverse industries such as manufacturing, automotive, aerospace, and robotics, where precision machinery requires safeguarding against external elements. The choice of rubber as the coating material ensures a high level of resistance to abrasion, chemicals, and environmental factors, making it a reliable option for long-term use.

In summary, rubber-coated bellows play a crucial role in protecting machinery by providing a flexible and durable barrier against external contaminants, contributing to the efficient and reliable operation of various industrial systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Bellow Covers' category

|

Mane Corporation

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry